Custom Adhesive Solutions & Services

Tailor-made adhesive solutions designed to meet your specific manufacturing and application needs.

Detailed Service Offerings

How We Can Help You?

Custom Formulation

Need specific adhesive properties, carrier materials, or performance characteristics? Our experienced R&D team develops unique formulations and tape constructions tailored precisely to your application challenges.

Precision Converting Services

Get adhesive tapes delivered exactly how you need them.Precision slitting to custom widths, complex rotary and flatbed die-cutting, multi-layer lamination, spooling, and more for seamless integration.

OEM/ODM Product Development

Partner with GMARK to develop and manufacture custom adhesive tape products under your brand. From concept and material selection to production and packaging, we provide end-to-end solutions.

Technical Support

Our experts help you select the right tape, optimize your application process, troubleshoot issues, and ensure you achieve the best possible results with our adhesive solutions.

Testing Services

We offer rapid prototyping for custom tape solutions and perform rigorous in-house testing (adhesion, shear, environmental exposure) to verify performance.

Material Expertise & Selection

Select the best combination based on the specific substrate, application environment and desired performance results.

OUR EXPERTISE

OUR CAPABILITIES

At GMARK, we go beyond standard products by offering a wide array of advanced in-house capabilities. From intricate material lamination and cutting to custom printing and specialized packaging, our technical expertise ensures we can create the perfect adhesive solution for your application.

GMARK specializes in bonding a wide variety of materials including films, foams and specialty adhesives to create high performance multi-layer composites. Our precision lamination process ensures optimal adhesion and material integrity

Adhesive Laminating

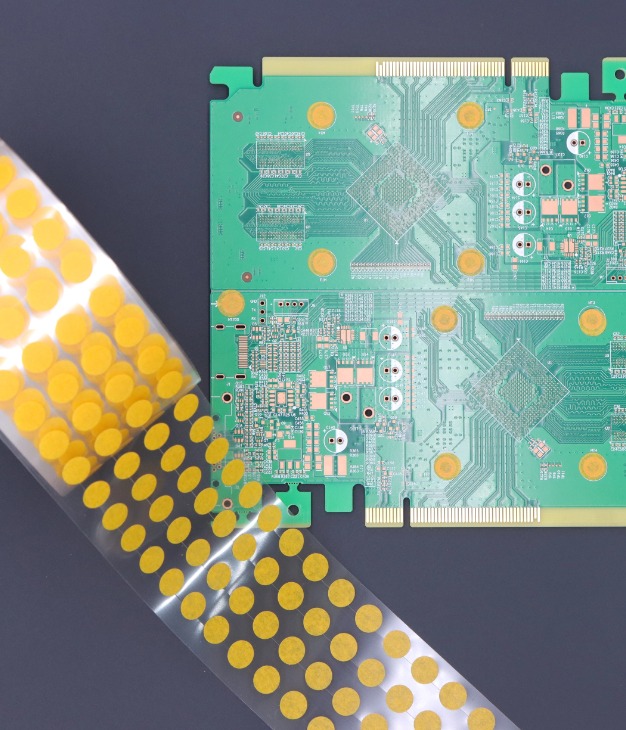

Our specialized foam slitting capabilities allow us to process a variety of foam materials (e.g. PE, PVC, EPDM, silicone foam) into rolls or strips of precisely customized widths. We are able to achieve tight tolerances, ensuring clean cuts and consistent dimensions for gasketing, sealing, cushioning and other critical foam applications.

Foam Tape Slitting

GMARK specializes in high-precision die cutting, transforming adhesive materials into intricate custom shapes, gaskets, and components. Utilizing advanced rotary and flatbed die-cutting technology, we deliver consistent, tight-tolerance parts, including kiss-cut components on a roll or individual pieces, meeting your exact design specifications.

Die Cutting

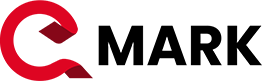

GMARK offers precision spooling services, winding long, continuous lengths of narrow adhesive tapes or foams onto spools. This optimizes material usage for automated application processes by significantly increasing run times and reducing the frequency of roll changes and splices, enhancing your production efficiency.

Spooled tape

Enhance your brand identity and product information with GMARK's custom printing services. We can print logos, branding elements, part numbers, or usage instructions directly onto tape cores, release liners, or the adhesive tape itself, offering a professional and customized presentation for your products.

Custom Printing

Beyond the tape itself, GMARK provides comprehensive custom packaging solutions to meet your specific branding, protection, and distribution needs. We offer a variety of options including individual plastic bag sealing, blister packs, custom-printed paper boxes, kitting, and specialized labeling (e.g., barcodes, batch codes) to ensure your products arrive safely and professionally presented.

Custom Packaging Solutions

Our Manufacturing Processes

Material Sourcing & Inspection

Carefully selected raw materials (adhesives, films, liners) are rigorously inspected upon arrival to ensure they meet our strict quality specifications before entering production.

Adhesive Coating & Lamination

Specialized adhesive formulations onto carrier films using advanced coating techniques, followed by controlled lamination with release liners for uniformity.

Curing OR Stabilization

Coated materials pass through controlled curing processes (e.g., thermal or UV) to achieve the desired adhesive properties and ensure long-term product stability and performance.

In-Process Quality Testing

Continuous monitoring and sample testing are performed at critical production stages (e.g., coat weight, thickness) to maintain consistent quality standards throughout the run.

Precision Rewinding

Master rolls are carefully rewound onto specified core sizes, ensuring consistent tension control and accurate length measurement, preparing them for subsequent converting steps.

Custom Cutting / Slitting / Die-Cutting

Utilizing advanced converting machinery for precision slitting into custom widths or die-cutting complex shapes and specific dimensions according to exact customer needs.

Final Quality Assurance

Finished tape products undergo a final comprehensive quality inspection, verifying all critical parameters including dimensions, appearance, and adhesive performance.

Packaging and Shipment

Products are carefully packaged to ensure protection during transit, accurately labeled, and prepared for reliable and timely shipment to meet customer delivery schedules globally.

Tailored Solutions, Tangible Result

At GMARK, every service engagement is focused on delivering tailored adhesive solutions that produce tangible results for your business. From enhancing product performance and durability to optimizing manufacturing processes and reducing costs, our expert team works to translate your specific needs into measurable outcomes. Experience the GMARK difference.

- Phone:(+86) 17803901720

- Email:[email protected]

- Address:No.7 Liyuan Road, Xuzhen Zone, Zhangmutou Town, Dongguan City, Guangdong, China

FAQ

General Question

Yes, GMARK is a manufacturer located in Dongguan with extensive experience providing custom adhesive tape solutions, including OEM/ODM, converting, and R&D services.

Simply contact us with your detailed requirements, including dimensions, shape (a drawing is helpful), material, application, and quantity. Our team will review your request and provide a tailored quote and proposal.

Absolutely. We can print logos on tape cores and cartons, and offer various special packaging options like individual shrink wrap with logo cards, barcode labeling, etc., as part of our OEM/ODM services. Please discuss your specific needs with us.

Please provide product specifications (material type, thickness, width, length), application details (what it's bonding, environment), required quantity, any specific converting needs (die-cut shape, slitting width), and packaging requirements.

Yes, we can often provide prototypes or samples as part of the development process. Please discuss sampling options and any associated costs with our team.

Lead times vary depending on the complexity of the project, material availability, and current production schedules. We will provide an estimated lead time with your quote.