Rufen Sie uns an

+86-17803901720

- STARTSEITE

- PRODUKTE

- PE-Schaumstoffe

- Acrylschaumstoffe

- PVC-Schaumstoffe

- EVA-Schaumstoffe

- EPDM & CR-Schaumstoffe

- Wasserlösliche Klebebänder

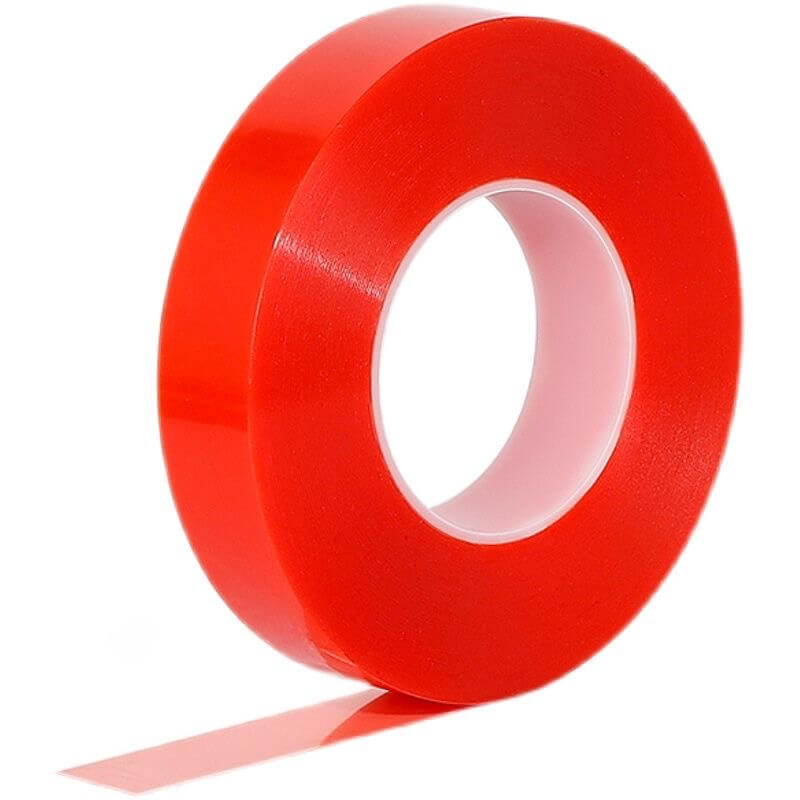

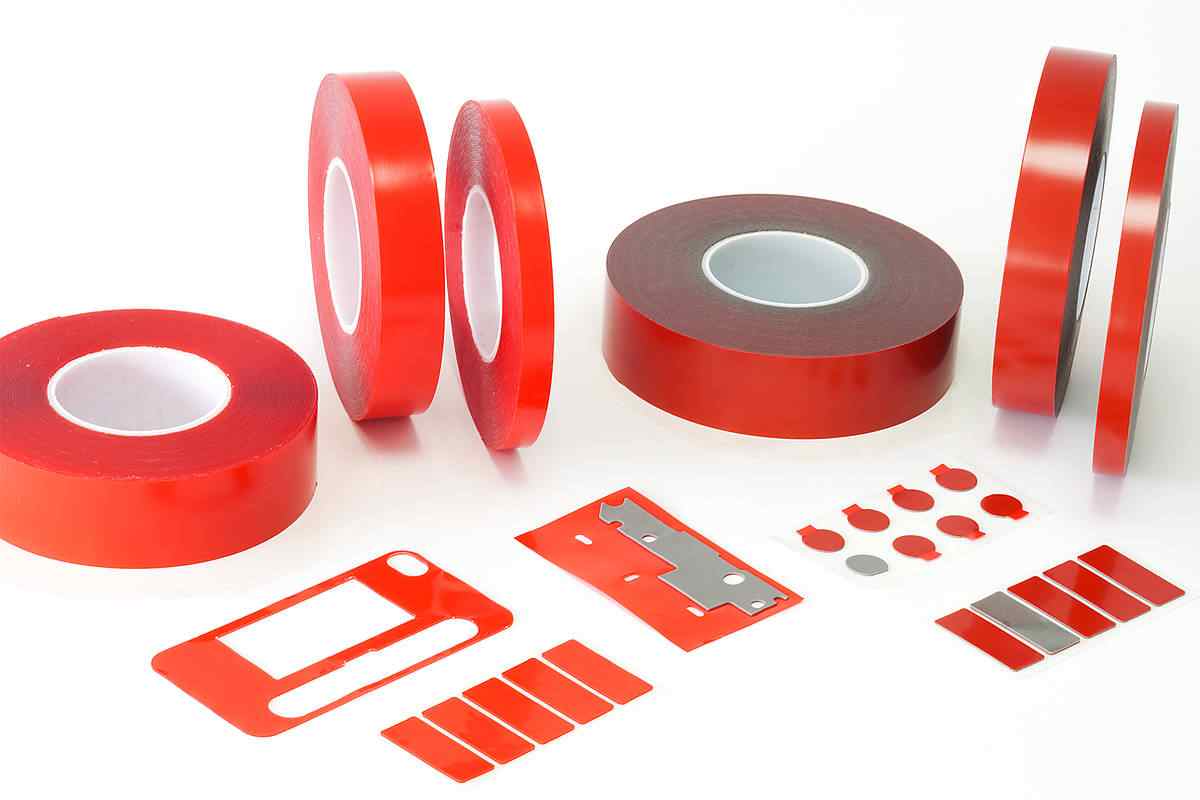

- Doppelseitige Klebebänder

- Doppelseitiges Transferklebeband

- Double sided PVC Tape

- Doppelseitiges PET-Klebeband

- Doppelseitiges Tissue-Klebeband

Schaumstoffband

DOPPELSEITIGES KLEBEBAND

Hochtemperaturklebeband

- WARUM GMARK WÄHLEN?

- SERVICELEISTUNGEN

- BLOG

- KONTAKT

DE

DE