اتصل بنا

+86-17803901720

- بيت

- منتجات

- أشرطة رغوة البولي إيثيلين

- أشرطة الرغوة الأكريليكية

- أشرطة رغوة البولي فينيل كلوريد

- أشرطة إسفنجية من مادة إي في إيه

- أشرطة رغوة EPDM&CR

- أشرطة قابلة للذوبان في الماء

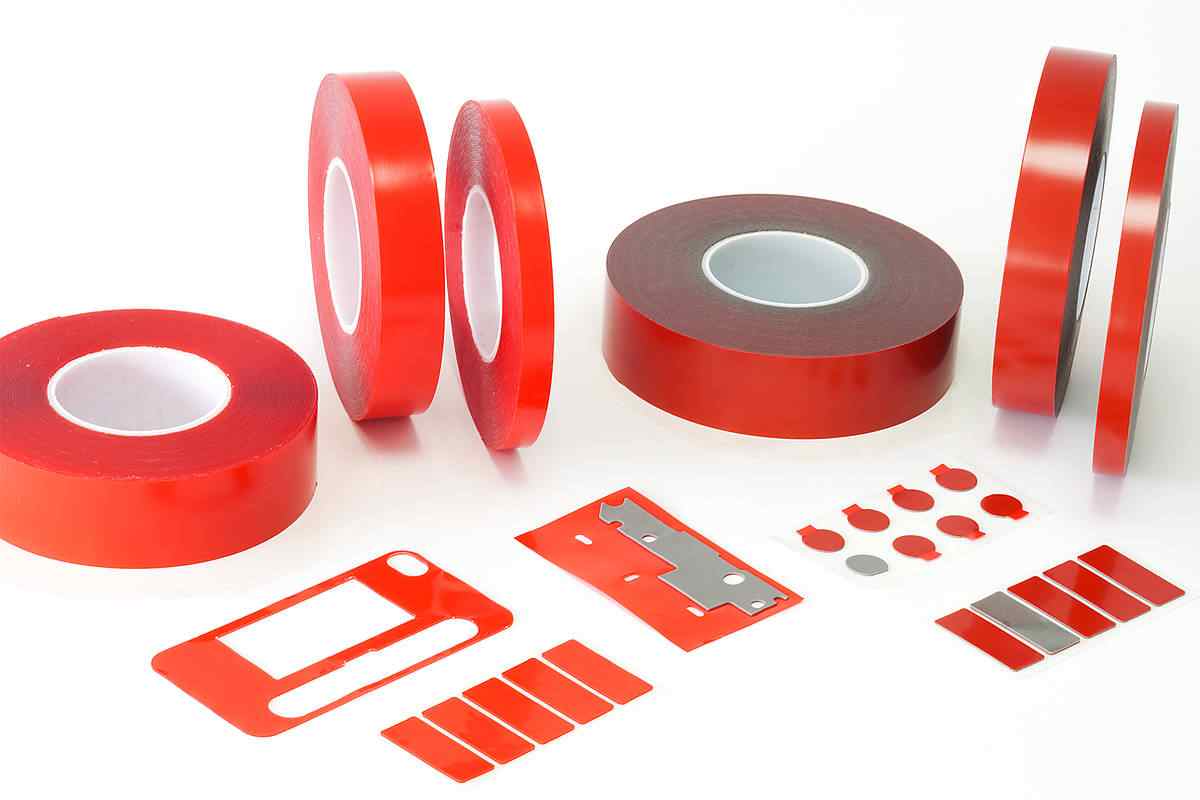

- أشرطة مزدوجة الجوانب

- شريط نقل لاصق مزدوج الجوانب

- شريط PVC مزدوج الوجه

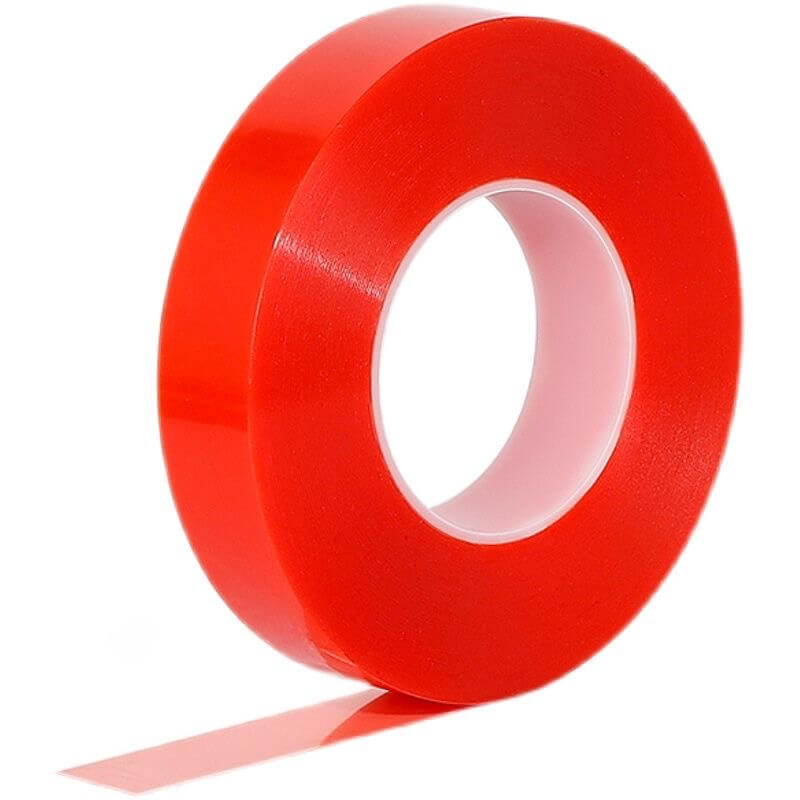

- شريط PET مزدوج الجوانب

- شريط ورقي لاصق مزدوج الجوانب

foam tape

DOUBLE SIDED TAPE

شريط درجة حرارة عالية

- لماذا تختار GMARK

- الخدمات

- مدونة

- اتصل بنا

AR

AR